Process & Power

Leading the way in innovation and sustainability

Customers in the Process segment focus on processing natural raw materials, such as oil, gas, and wood into semi-finished and end-products. Our products are applied in industries such as the petrochemical, chemical, food, pharmaceutical, and paper industries, as well as in water treatment and waste processing plants. The Power segment, on the other hand, focuses on power generation, including both thermal and renewable energy.

In this edition of VL Together, we shine a spotlight on the dynamic Process & Power market segment, highlighting our Essen office in Germany, which specializes in meeting the unique demands of this sector. We talked with Meikel Pitsch, Commercial Director of Van Leeuwen GmbH to explore how he and his team in Essen are driving innovation and sustainabilty.

Back to index

Van Leeuwen Process & Power

“Van Leeuwen Process & Power in Essen, Germany, plays an important role in this market segment by leading the way in providing innovative solutions tailored to meet the unique needs of our customers” Meikel says. Located within a vibrant industrial area, our Essen office boasts a team of experienced professionals who are not just technologically adept but also deeply connected to the needs and challenges of our customers. “Both our affinity with technology and proximity to customers allow us to stay at the forefront of industry trends and swiftly adapt to changing requirements. Our focus on delivering tailored solutions ensures that our customers receive comprehensive, value-added services such as coating, finning, welding special parts, and engineering, exceeding their expectations.” Meikel continues.

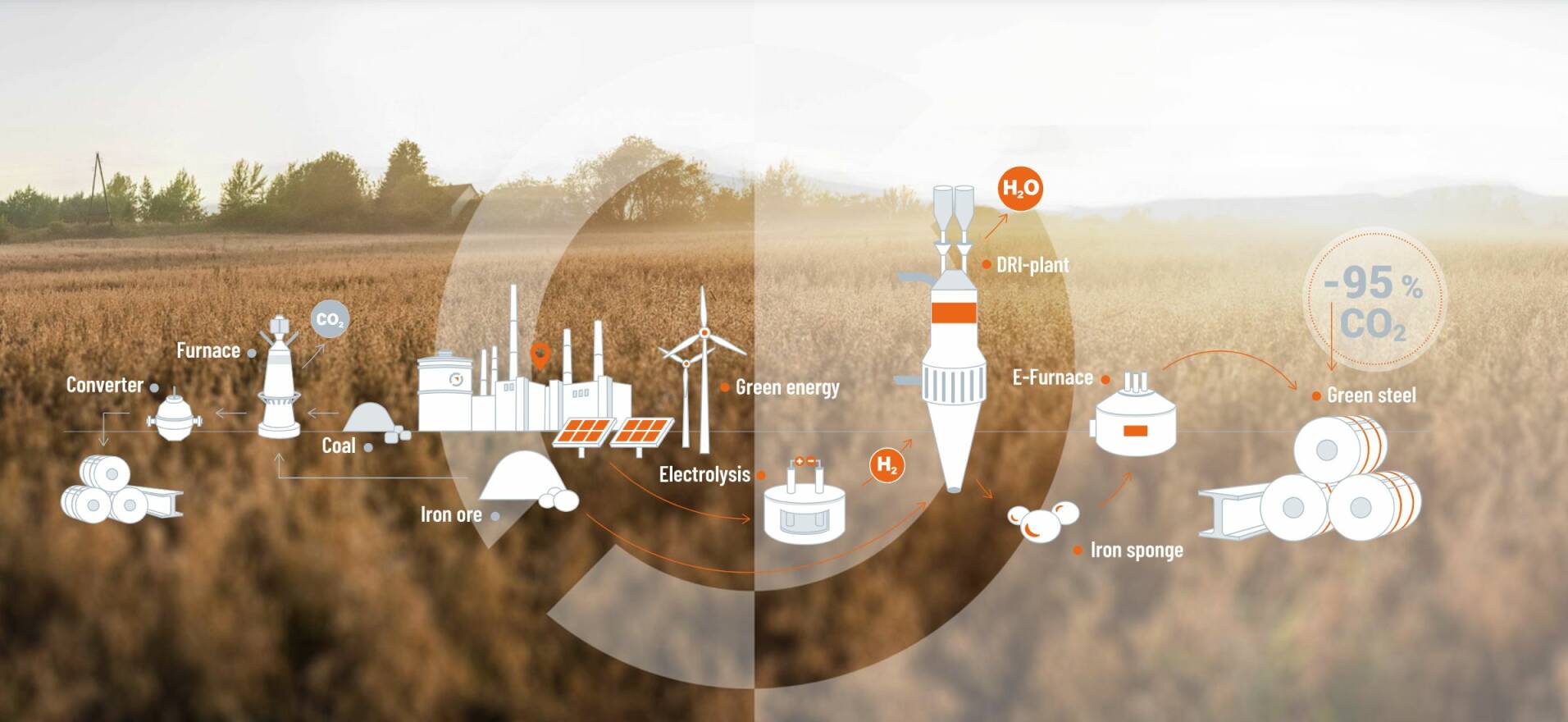

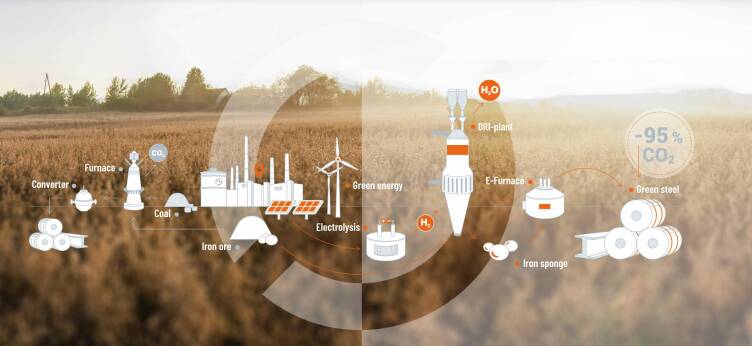

SALCOS®

The SALCOS® (Salzgitter Low CO2 Steelmaking) program aims for near climate-neutral steel production using renewable electricity and green hydrogen to replace coal in the blast furnace process. Iron ore is reduced to iron directly in its solid-state using hydrogen, emitting water vapor instead of CO2. This Carbon Direct Avoidance Strategy will cut CO2 emissions by over 95%.

Heilbronn powerplant: from coal to natural gas to hydrogen

Sener project for EnBW:

EnBW has started construction on a new power plant in Heilbronn, Germany, as part of their transition from coal to cleaner energy. This project, in collaboration with amongst others Sener (Spain), aims to deliver 710 MW of electricity and 190 MW of district heating by 2026. The plant will reduce carbon emissions by over 50% and support the modernization of the district heating grid.

Bilfinger Nuclear and the Hinkley Point C project:

Bilfinger is an international industrial services provider for the process industry. One of their large projects is Hinkley Point C, located in the southwest of England. It is the first new nuclear power plant to be built in the United Kingdom in over 25 years. It will supply around 6 million households with electricity, help reduce carbon dioxide emissions and ensure the security of energy supplies in the future.

Construction site of Hinkley Point C

Industry engagements and achievements

Van Leeuwen Process & Power's Nuclear Team showcased their expertise at the World Nuclear Exhibition (WNE) in Paris, coinciding with their ISO 19443 certification audit. Their presentation highlighted capabilities in the nuclear industry, positioning them as key players and achieving zero non-conformity in the audit, which solidified their commitment to quality management and nuclear safety. At the 38th VAIS Technical Conference, Van Leeuwen Essen discussed challenges and opportunities in power plant construction and the chemical industries, aligning their services with future industry trends. Additionally, at the 55th Kraftwerkstechnisches Kolloquium in Dresden, they participated in discussions focused on materials and services for the power sector, showcasing their dedication to advanced, sustainable solutions and reinforcing their commitment to innovation and sustainability.

“Van Leeuwen Process & Power has shown exceptional leadership by entering the nuclear sector. Our commitment to innovation and sustainability drives us forward, pioneering new technologies to redefine industry standards.”

Meikel Pitsch - Commercial Director Van Leeuwen GmbH (Essen)

Key projects and customers

Van Leeuwen Process & Power has recently secured a significant project with Sener in Spain for EnBW Germany and continues its valued collaboration with Bilfinger Nuclear, supplying critical components for the Hinkley Point facility. Van Leeuwen Germany welcomed the Bilfinger team to the central warehouse in Duisburg, where discussions focused on enhancing support for Bilfinger’s projects with tailored solutions. This visit underscored the strength of our partnership, highlighting our commitment to seamless connections and leveraging Bilfinger’s network for customized materials and prefabrication solutions.

Recent portfolio also includes waste-to-energy plants and battery production facilities for esteemed customers were we supply CO2 reduced SALCOS® products from Salzgitter.

History of Van Leeuwen in Essen

Before the Essen team became a part of the Van Leeuwen Pipe and Tube Group, the team operated under the name “Ferrostaal Piping Supply,” based in Essen but with locations in Vechta, Germany, and a small project warehouse in Hooge Zwaluwe, the Netherlands. The Vechta office has specialized in handling the ExxonMobil MRO contract in Germany for 20 years. The focus of the sales teams in Essen and Hooge Zwaluwe was on projects, shutdowns, and special requirements. In April 2018, Ferrostaal Piping Supply became a part of the Van Leeuwen Pipe and Tube Group. The Essen team started focusing on project business and significantly increased the turnover in this segment. At the end of 2023, Van Leeuwen Process & Power relocated to a new office in the heart of Essen. “The new premises symbolize Van Leeuwen Process & Power’s expansion and strategic objectives. Today, the Essen office employs 50 dedicated professionals committed to delivering excellence in every project.” Pitsch explains with pride.

SALCOS®

The SALCOS® (Salzgitter Low CO2 Steelmaking) program aims for near climate-neutral steel production using renewable electricity and green hydrogen to replace coal in the blast furnace process. Iron ore is reduced to iron directly in its solid-state using hydrogen, emitting water vapor instead of CO2. This Carbon Direct Avoidance Strategy will cut CO2 emissions by over 95%.

Bilfinger Nuclear and the Hinkley Point C project:

Bilfinger is an international industrial services provider for the process industry. One of their large projects is Hinkley Point C, located in the southwest of England. It is the first new nuclear power plant to be built in the United Kingdom in over 25 years. It will supply around 6 million households with electricity, help reduce carbon dioxide emissions and ensure the security of energy supplies in the future.

Construction site of Hinkley Point C

Heilbronn powerplant: from coal to natural gas to hydrogen

Sener project for EnBW:

EnBW has started construction on a new power plant in Heilbronn, Germany, as part of their transition from coal to cleaner energy. This project, in collaboration with amongst others Sener (Spain), aims to deliver 710 MW of electricity and 190 MW of district heating by 2026. The plant will reduce carbon emissions by over 50% and support the modernization of the district heating grid.

Key projects and customers

Van Leeuwen Process & Power has recently secured a significant project with Sener in Spain for EnBW Germany and continues its valued collaboration with Bilfinger Nuclear, supplying critical components for the Hinkley Point facility. Van Leeuwen Germany welcomed the Bilfinger team to the central warehouse in Duisburg, where discussions focused on enhancing support for Bilfinger’s projects with tailored solutions. This visit underscored the strength of our partnership, highlighting our commitment to seamless connections and leveraging Bilfinger’s network for customized materials and prefabrication solutions.

Recent portfolio also includes waste-to-energy plants and battery production facilities for esteemed customers were we supply CO2 reduced SALCOS® products from Salzgitter.

“Van Leeuwen Process & Power has shown exceptional leadership by entering the nuclear sector. Our commitment to innovation and sustainability drives us forward, pioneering new technologies to redefine industry standards.”

Meikel Pitsch - Commercial Director Van Leeuwen GmbH (Essen)

Before the Essen team became a part of the Van Leeuwen Pipe and Tube Group, the team operated under the name “Ferrostaal Piping Supply,” based in Essen but with locations in Vechta, Germany, and a small project warehouse in Hooge Zwaluwe, the Netherlands. The Vechta office has specialized in handling the ExxonMobil MRO contract in Germany for 20 years. The focus of the sales teams in Essen and Hooge Zwaluwe was on projects, shutdowns, and special requirements. In April 2018, Ferrostaal Piping Supply became a part of the Van Leeuwen Pipe and Tube Group. The Essen team started focusing on project business and significantly increased the turnover in this segment. At the end of 2023, Van Leeuwen Process & Power relocated to a new office in the heart of Essen. “The new premises symbolize Van Leeuwen Process & Power’s expansion and strategic objectives. Today, the Essen office employs 50 dedicated professionals committed to delivering excellence in every project.” Pitsch explains with pride.

History of Van Leeuwen in Essen

Customers in the Process segment focus on processing natural raw materials, such as oil, gas, and wood into semi-finished and end-products. Our products are applied in industries such as the petrochemical, chemical, food, pharmaceutical, and paper industries, as well as in water treatment and waste processing plants. The Power segment, on the other hand, focuses on power generation, including both thermal and renewable energy.

In this edition of VL Together, we shine a spotlight on the dynamic Process & Power market segment, highlighting our Essen office in Germany, which specializes in meeting the unique demands of this sector. We talked with Meikel Pitsch, Commercial Director of Van Leeuwen GmbH to explore how he and his team in Essen are driving innovation and sustainabilty.

“Van Leeuwen Process & Power in Essen, Germany, plays an important role in this market segment by leading the way in providing innovative solutions tailored to meet the unique needs of our customers” Meikel says. Located within a vibrant industrial area, our Essen office boasts a team of experienced professionals who are not just technologically adept but also deeply connected to the needs and challenges of our customers. “Both our affinity with technology and proximity to customers allow us to stay at the forefront of industry trends and swiftly adapt to changing requirements. Our focus on delivering tailored solutions ensures that our customers receive comprehensive, value-added services such as coating, finning, welding special parts, and engineering, exceeding their expectations.” Meikel continues.

Van Leeuwen Process & Power

Process & Power

Industry engagements and achievements

Van Leeuwen Process & Power's Nuclear Team showcased their expertise at the World Nuclear Exhibition (WNE) in Paris, coinciding with their ISO 19443 certification audit. Their presentation highlighted capabilities in the nuclear industry, positioning them as key players and achieving zero non-conformity in the audit, which solidified their commitment to quality management and nuclear safety. At the 38th VAIS Technical Conference, Van Leeuwen Essen discussed challenges and opportunities in power plant construction and the chemical industries, aligning their services with future industry trends. Additionally, at the 55th Kraftwerkstechnisches Kolloquium in Dresden, they participated in discussions focused on materials and services for the power sector, showcasing their dedication to advanced, sustainable solutions and reinforcing their commitment to innovation and sustainability.

Leading the way in innovation and sustainability

Terug naar overzicht

Cem Senkaya

Regional Sales Manager

Back to index